11.28.2020

Post plastic 3d printer: our project :)

Is it possible to combine the needs of recycling and reuse of waste with design, art, production, commercial and distribution processes? Is it possible to do it through collective management of the necessary technological tools?

We really think so and we believe it is possible with a very low investment, in an economically self-sustainable way, with very low CO2 emissions for the benefit of everyone.

We believe it is possible and desirable!

????What is lab! Puzzle? (where it is not a detail)

WE WANT TO REALIZE OUR PROJECT IN A RECEPTIVE SPACE, VALUABLE, BY NATURE IN LINE WITH THE PRINCIPLES WE CARE ABOUT. Lab! Puzzle is an urban civic common good in Rome in the montesacro district, democratic, accessible, completely self-financed … A social center animated by a community with the aim of mending the social fabric, developing a critical sense, producing services for the territory.Among the many activities that have sprung up there is the TUTTOFARE WORKSHOP that deals with repairs of all kinds, of creative recycling, FIGHT AGAINST UNBELIEVABLE CONSUMPTION AND PROGRAMMED OBSOLESCENCE … a workshop part of the “repair caffè” network, which connects more than two thousand hubs all over the world … this is where we want to start The project

????The project

Did you know that half of all the plastic on our planet was produced in just the last 15 years? And that the quantity produced is eight times greater than that recycled?

The plastic we throw away is mostly compacted in huge landfills or burned; from recycled plastic are obtained just a low quality material is obtained, suitable for few uses.

This means that a water bottle will not go back to being a water bottle, forcing the production of new plastic. .

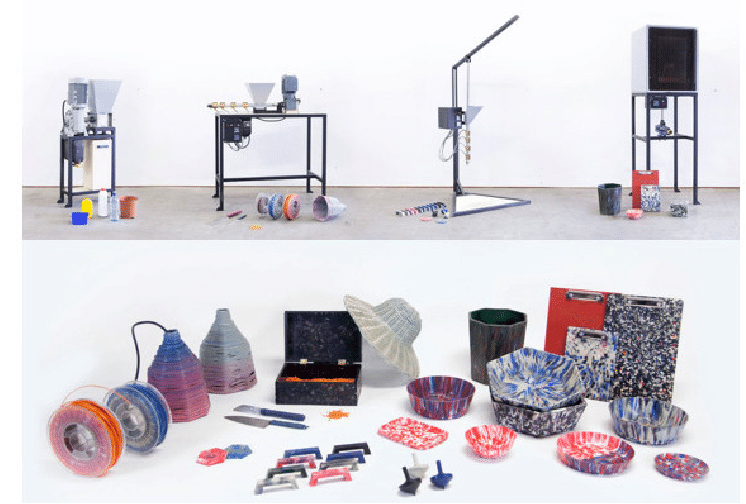

The PPP (post plastic 3d printer) project allows us to better differentiate and recycle on our own *, to produce starting from a heap of waste destined for landfill (or for an approximate differentiation) COMMON USE OBJECTS, SPARE PARTS THAT CANNOT BE FOUND ON THE MARKET and CREATIVE WORKS … in short, something useful and / or beautiful with a job of a few hours, from something that has nothing beautiful and useful.

In this way we can reduce the direct creation of new plastics from oil, stop its unconditional accumulation.

????HOW DOES IT WORK?

The carefully sorted plastic waste is reduced to small granules

through a CO2-neutral extrusion process, they become thin filaments

Through the modeling software and the 3D printer, they turn into solid objects, with the shape and function you need!

What we want is to create an important precedent, replicable, free, based on the DIY LOGIC (“do it yourself”) …

We want to make this technology accessible to anyone and for free to learn, experiment, export knowledge …

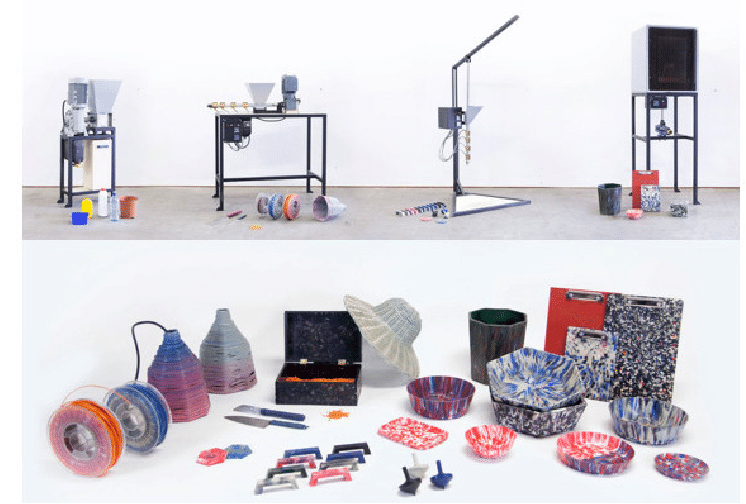

????WHAT IS NEEDED?

To achieve all this we need machinery: few, but necessary; creativity and manual skill are “raw materials” that we already have.

1) a plastic grinder: to shred waste (previously separated by type of resin)

2) an extruder that, without combustion, transforms the plastic strings into filaments that can be used as meteria prima for 3D prints

3) a 3D printer.

4) a personal computer capable of processing 3D models. because we believe the circular economy, its automation and the collective management of the necessary tools are viable, the best ways to achieve better world! … A dream isn’t it?

????Let’s recap the strengths of this project:

– It is designed to be accessible to anyone and free of charge

– It has low costs

– Complete replicability (the projects are open source, as well as free and implementable 3d model archives on the network)

– Reduces environmental impact (reuse of plastic materials at km0)

-Stimulates creativity

-Allows the creation at no cost, of objects of all types and shapes!

Click the link, make your donation 🙂 🙂